Why COVID and the War in Ukraine Have Made Things So different

If you’ve been shopping for high-quality furniture or working on a home project lately, you’ve probably noticed something odd. Birch plywood, especially the good stuff—furniture-grade—has become super hard to find. And if you do find it, you’re probably paying a lot more than you used to. What’s going on? Well, it all comes down to a couple of major events that have turned the market upside down: the COVID-19 pandemic and the ongoing war in Ukraine. Oh, and to make things worse, the highest grade of B/B birch plywood? It’s basically off the market now. Let’s dive into what’s happening and why.

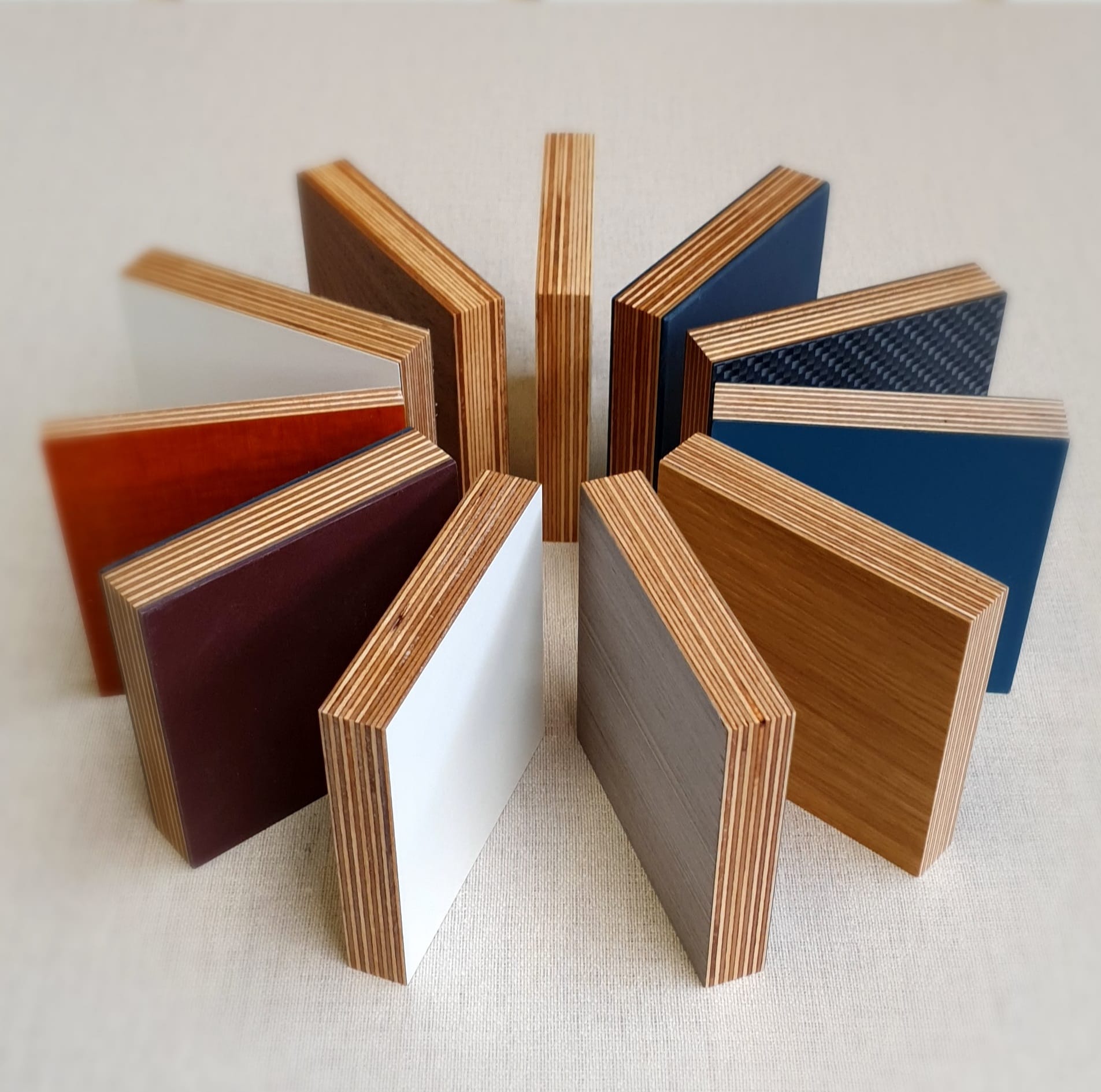

Photo by MW Creative Carpentry

COVID-19: The First Big Disruptor

1. Factories Slowing Down or Shutting Down

Remember when COVID first hit and everything came to a screeching halt? That included factories that make birch plywood. Countries like Russia, Finland, and the Baltic states—big players in plywood production—either shut down their factories or scaled way back to follow health restrictions. Workers were either sick, scared, or just not available. That meant production slowed down big time, creating huge backlogs.

2. Shipping Got Messy

On top of that, global shipping became a nightmare. Shipping containers were stuck in the wrong places, ports were jammed, and costs to ship anything—including birch plywood—went through the roof. It took weeks or even months to get stuff that used to arrive in a matter of days. Naturally, all of this made plywood more expensive and harder to get.

3. Everyone Became a DIYer

Now, here’s the twist. While supply chains were struggling, demand for plywood went through the roof. Stuck at home, people started tackling all those DIY projects they’d been putting off. Home office builds, new furniture, kitchen makeovers—you name it. Everyone wanted plywood at the exact moment it was hardest to get. Perfect storm, right?

Then Came the War in Ukraine

1. Russia Was a Major Player

Here’s the thing: Russia was one of the biggest suppliers of birch plywood in the world. Its forests are packed with birch trees, and its factories were cranking out plywood at a massive scale. But when Russia invaded Ukraine in 2022, everything changed. Western countries slapped sanctions on Russia, cutting off its birch plywood exports. Suddenly, a huge chunk of the market disappeared overnight.

2. Where Else Could We Go?

So, if we couldn’t buy from Russia, we had to look elsewhere. Countries like Finland and Latvia tried to pick up the slack, but they just couldn’t match Russia’s scale or low costs. The result? Even more pressure on the global supply chain, and prices kept climbing.

3. Ukraine and Belarus Also Took Hits

It wasn’t just Russia. Ukraine, which has its own growing woodworking industry, saw its factories shut down or damaged by the war. Belarus, another birch plywood exporter, got hit with sanctions because of its ties to Russia. Basically, every major source of birch plywood in the region was affected, and the rest of the world is still scrambling to fill the gap.

The Bigger Picture: Environmental and Logistical Issues

1. Sustainable Forestry Under Stress

When one big source of birch plywood disappears, everyone turns to the next available option. That’s put a lot of pressure on forests outside Russia. Countries trying to ramp up production now have to balance meeting demand with protecting their forests. It’s a tough call, and there’s a real risk of overharvesting, which could create long-term problems.

2. Adjusting Supply Chains Is Hard

Finding new suppliers sounds easy on paper, but in reality, it’s a logistical headache. Different countries have different plywood specs, and it takes time to build new trade routes and relationships. All of this adds delays and costs, making the shortage even worse.

What’s This Doing to Prices and Options?

1. Higher Costs for Everyone

If you’re in the furniture business, you’re feeling the squeeze. Manufacturers are paying way more for materials, and a lot of them have no choice but to pass those costs onto customers. For smaller businesses, it’s even harder. Some are barely hanging on, while others have been forced to shut down.

2. Alternatives Aren’t Great

Sure, there are other options, like MDF or particleboard. But let’s be honest: they’re not the same. Birch plywood is prized for being strong, durable, and beautiful. None of the alternatives really check all those boxes. Plus, even these substitutes are getting more expensive because of the overlapping supply chain issues.

3. No More B/B Birch Plywood

And here’s the kicker: the highest grade of birch plywood, B/B, is gone. This was the go-to material for premium furniture and cabinetry, and now it’s just not an option. That’s left manufacturers and DIYers scrambling to make do with lower-quality materials, which isn’t ideal.

What Can We Do About It?

1. Find New Sources

One solution is to start producing birch plywood in untapped areas, like Canada or other parts of Scandinavia. But that’s easier said than done. It takes time, money, and sustainable practices to ramp up production.

2. Look for Alternatives

Scientists and engineers are working on creating new materials that can mimic the properties of birch plywood. These engineered woods and composites could help fill the gap, but they’re still in development and not widely available yet.

3. Work Together

Governments, industries, and environmental groups need to team up to fix this. Policies that promote sustainable forestry, support innovation, and encourage fair trade practices could make a big difference.

4. Adapt to the New Normal

For now, we all need to adjust. Manufacturers might need to experiment with alternative materials, and consumers might have to accept higher prices or longer wait times. It’s not ideal, but it’s the reality we’re in.

Wrapping It Up

So, that’s the story behind the birch plywood shortage. COVID-19 and the war in Ukraine turned supply chains inside out, and now we’re all feeling the impact. The disappearance of B/B grade birch plywood is just one more blow in a tough situation. But challenges like these also spark innovation and collaboration. With some time and effort, the industry can bounce back—hopefully stronger and more sustainable than before.